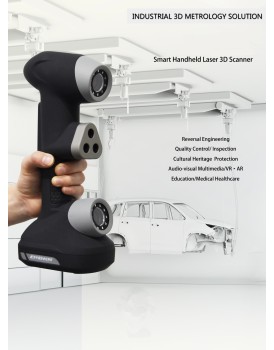

New Shine White Light double eyes 3d scanner Product Details Specifications

1. Model: NS3DM2.Single scan range : 200*150 , 100*75, 50*403.Single measurement accuracy: 200*150 , 100*75, 50*40: 0.01~0.0153.sampling pitch radiography : 200*150: 0.15 , 100*75:0.06 , 50*40:0.034.Scan Object size : 200*150: 100~1000mm , 100*75: 50~150mm, 50*40 <50mm5 Measurement method :White light Non-contact surface measurement model.6.Digital Splicing method : Dotted mosaic automatic iden..

| Product Code: | NS-112 |

| Availability: | 1 |

| 1. Model: NS3DM | ||

| 2.Single scan range : 200*150 , 100*75, 50*40 | 3.Single measurement accuracy: 200*150 , 100*75, 50*40: 0.01~0.015 | |

| 3.sampling pitch radiography : 200*150: 0.15 , 100*75:0.06 , 50*40:0.03 | 4.Scan Object size : 200*150: 100~1000mm , 100*75: 50~150mm, 50*40 <50mm | |

| 5 Measurement method :White light Non-contact surface measurement model. | 6.Digital Splicing method : Dotted mosaic automatic identification stitching | |

| 7.Camera Sensor: Industrial camera 200M pixel *2 pcs . | 8.Industrial lens: industrial Lens 300M pixel *2 | |

| 9.Grating system : America DLP digital raster heterodyne multi-frequency phase-shift , novel area-modulated phase-shifting binary method for three-dimensional (3D) shape measurement. | 10.Grating light source : LED cold light source , life expectancy: 35000 Hours . | |

| 11. Scan type Non-contact structure light scanning. | 12. Output Data format: ACS , OBJ, STL , ,PLY, IGES. | |

| 13 . Scan time : < 3 sec | 14. Operation system : win 98 / NT / 2000/XP/Win 7 / Win 10 64 | |

| 15.Applicable Filed : 200*150: sole ,shoes wood carving and other medium-sized components, 100*75 : jade carving hardware consumer electronics, 50*40 : ultra-precision jade hardware earphone film and so on. | ||

| 16.Memory usage : Supporting large memory more than 32G | Voltage: 100-230V,50/60HZ |

Items description :

1.Efficient and Reliable Scanning.

Precision 3D Scanner is a precision engraving, ball jewelry and other fine objects scanning Professional equipment, the minimum scanning pitch up to 0.03mm, the details of the lines clearly visible, high-precision measurement of complex surfaces For simple and quick.

The Use of 3d scanner

Jade carving, ball treasure jewelry, precision engraving and other high-precision scanning industry.

2.Convenient Scanning

Equipped with 3 sets of scan ranges, suitable for 3D measurement and inspection including these heavy and large objects.

3.Portable

Small and portable, can be applied in various conditions.metal flight case .

4.Full Dimension Measurement and Inspection

Non-contact measurement can be applied in complex component to get full dimension inspection and measurement.

Feature and Advantage

1)long product life, high-brightness LED cold light source, low fever, high scanning accuracy and stability

2) The hardware is stable, the system body is small, easy to disassemble, easy to bring to the measurement site.

3) Can scan dark or even black objects. Most objects can be directly scanned without surface treatment.

4) Scanning efficiency, object scanning can be completed within a few minutes.

5) dual camera using strict hardware synchronization mechanism, the measurement data clearer.

6) The use of aluminum body, thermal deformation coefficient is small, to ensure higher accuracy and stability of equipment.

7) Multiple point cloud automatic splicing.

8) Support for overlapping point cloud automatically select the best data, automatic cutting, multiple data fusion high precision, no points , Layer and stripes.

9) The appearance of a solid compact design makes the device more visual impact, beautiful equipment, lightweight, durable.

10) Equipped with a lens hood to prevent damage to the lens caused by accidental drop of equipment.

11) easy to learn and use, you can learn system operation in 2 hours, 1-2 working days can be used skillfully

12) a multi-purpose machine, a variety of scanning specifications, as small as a few millimeters up to a few meters of object scanning

13) Measurement output data interface is rich: The measured point cloud data is ASC, STL, PLY, IGES, OBJ, DXF, etc.,

14) Compatible with common 3D software in the market.

.png)