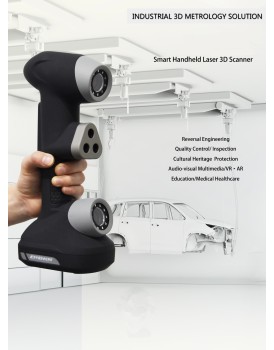

New Shine Blue Light Four eyes 3d scanner Product Details Specifications

New Shine Blue Light Four eyes 3d scanner 1. Model: NS3DBII2.Single scan range : 400*300 , 200*150,100*75, 50*403.Single measurement accuracy: 400*300 , 200*150 : 0.015~0.025 , 100*75, 50*40: 0.01~0.0153.sampling pitch radiography : 400*300: 0.3 , 200*150: 0.15 , 100*75:0.06 , 50*40:0.034.Scan Object size : 400*300 : 400~5000mm , 200*150: 100~400mm , 100*75: 50~100mm, 5..

| Product Code: | NS-112 |

| Availability: | 1 |

New Shine Blue Light Four eyes 3d scanner 1. Model: NS3DBII | ||

| 2.Single scan range : 400*300 , 200*150,100*75, 50*40 | 3.Single measurement accuracy: 400*300 , 200*150 : 0.015~0.025 , 100*75, 50*40: 0.01~0.015 | |

| 3.sampling pitch radiography : 400*300: 0.3 , 200*150: 0.15 , 100*75:0.06 , 50*40:0.03 | 4.Scan Object size : 400*300 : 400~5000mm , 200*150: 100~400mm , 100*75: 50~100mm, 50*40 <50mm | |

| 5 Measurement method :Non-contact surface measurement model. | 6.Digital Splicing method : Dotted mosaic automatic identification stitching | |

| 7.Camera Sensor: Industrial camera 130 M pixel *4 pcs . | 8.Industrial lens: industrial Lens 300M pixel *4 | |

| 9.Grating system : America DLP digital raster heterodyne multi-frequency phase-shift , novel area-modulated phase-shifting binary method for three-dimensional (3D) shape measurement. | 10.Grating light source : LED cold light source , life expectancy: 35000 Hours . | |

| 11. Scan type Non-contact structure light scanning. | 12. Output Data format: ACS , OBJ, STL , ,PLY, IGES. | |

| 13 . Scan time : < 5 sec | 14. Operation system : win 98 / NT / 2000/XP/Win 7 / Win 10 64 | |

| 15.Applicable Filed : 400*300 : Auto parts vehicle appliances , large molds sculptures. 200*150: sole ,shoes wood carving and other medium-sized components, 100*75 : jade carving hardware consumer electronics, 50*40 : ultra-precision jade hardware earphone film and so on. | ||

| 16.Memory usage : Supporting large memory more than 32G | Voltage: 100-230V,50/60HZ |

Feature:

1.Efficient and Reliable Scanning.

Less than 5s for a single scan . It takes around 30 minutes to scan a 1-meter-long object and get a high accuracy and resolution result

2.Convenient Scanning

Equipped with 3 sets of scan ranges, suitable for 3D measurement and inspection including these heavy and large objects.

3.Portable

Small and portable, can be applied in various conditions.metal flight case .

4.Full Dimension Measurement and Inspection

Non-contact measurement can be applied in complex component to get full dimension inspection and measurement.

Feature and Advantage

1) the latest generation of non-contact blue-ray scanning technology;

2) Support for overlapping point cloud automatically select the best data, multiple data fusion, high precision, no stratification and stripes

3) The appearance of a solid compact design, beautiful equipment, lightweight, durable.

4) Japan imported optical low distortion lens, the United States imported grating

5) high measurement accuracy, measurement accuracy up to 0.01mm ~ 0.03mm

6) easy to learn and use, you can learn system operation in 2 hours, 1-2 working days can be used skillfully

7) a multi-purpose machine, a variety of scanning specifications, as small as a few millimeters up to a few meters of object scanning

8) Measurement output data interface is rich: The measured point cloud data is ASC, STL, PLY, IGES, OBJ, DXF, etc.,

Compatible with common 3D software in the market.

.png)