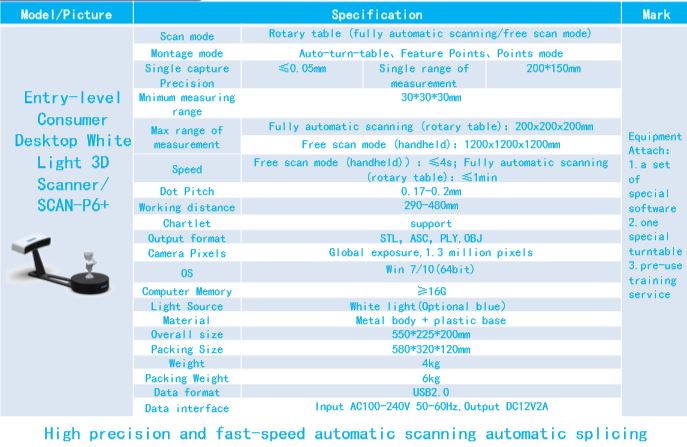

New Shine Entry-level Consumer Desktop White Light 3D Scanner/ SCAN-P6+

New Shine Entry-level Consumer Desktop White Light 3D Scanner/ SCAN-P6+New Shine Entry-level Consumer Desktop White Light 3D Scanner/ SCAN-P6+ 1.High precision: the precision is 0.05mm, with more details.2. Fast scanning: automatic scanning mode of rotary table, single scan within 4 seconds, 1 minute for a circle.3. Dual-mode scanning: it can flexibly switch between automatic scanning and..

| Brand: | New Shine |

| Product Code: | NS-P6 |

| Availability: | 10 |

New Shine Entry-level Consumer Desktop White Light 3D Scanner/ SCAN-P6+

New Shine Entry-level Consumer Desktop

White Light 3D Scanner/ SCAN-P6+

1.High precision: the precision is 0.05mm,

with more details.

2. Fast scanning: automatic scanning mode

of rotary table, single scan within 4 seconds, 1 minute for a circle.

3. Dual-mode scanning: it can flexibly

switch between automatic scanning and free scanning modes. Under automatic

scanning mode, the maximum scanning range is 200mm*200mm*200;In free scanning

mode, the maximum scanning range is 1200mm*1200mm*1200mm.

4. No connection with 3D printing: after

scanning, STL data can be directly output In 3D printing, seamless connection

5. Metal body: integrated design, good

rigidity, more stable scanning.

6. Security: white light scan is more

secure (blue light is optional), color mapping is available.

7. High cost performance: consumer price,

quasi-industrial performance.

3D Scanner Usage Flow

1.

Calibration Proofread the

position distance between the scanner and the workpiece to be scanned.

2.

3.

Surface treatment of the object

under test Three-dimensional scanning of the surface of the object is also

required, for translucent or material (glass, reflective objects), or a darker

color of the workpiece is difficult to scan. This requires spraying a thin

layer of imaging agent on the surface of the workpiece (imaging agent will not

cause damage to the surface of the object and the human body, after the

completion of scanning with clean water can be removed), in order to better

scan the three-dimensional characteristics of the object, the data will be more

accurate.

4.

3.Start scanning After the preparation

work, the object can be scanned, the 3D data of the scanned object can be

captured from different angles, the object placement mode can be changed or the

3D scanner camera direction can be adjusted, and the object can be scanned 360

degrees.

5.

Data processing later The 3D

scanner software system can automatically splice the scanned point cloud data

without manual splice. After scanning, the system will automatically generate

threedimensional point cloud graphics, and the system software will

automatically convert the point cloud data directly into the network format

(STL,OBJ) required by customers, etc. The generated data can be connected with

the 3D software.

3D Scanner Industry Applications and Uses

1.

Industry Applications

Quasi-industrial grade, with marking point alignment, suitable for scanning

industrial or large objects, can be used in shoes, underwear mold, carving

engraving industry, glass products, 3d digital education, art design.

2.Uses

A.Reverse design (reverse engineering) : Customers have physical

objects and need 3D models of physical objects. They use 3D scanner to conduct

3D scanning, and then import the scanned 3D models into Catia, Proe,UG, 3D Max,

Maya and other 3D software for 3D digitization. This process is called reverse

design.

B.3D detection: In order to ensure the reasonable physical size

after processing, we need conventional testing tools to detect whether there is

any deviation in the physical size after processing, which is not only

inefficient, but also difficult to detect some dimensions. After the processed

object is scanned and the 3D model is

obtained, the scanned model is imported into the detection software for

detection, which is not only efficient and convenient, but also of higher

detection accuracy.The 3D model scanned by 3D scanner can be directly imported

into 3D printer for printing, which has a good combination with 3D printing

technology.

If you need precise scan , please choose p6+ , thank you for your help.

.png)